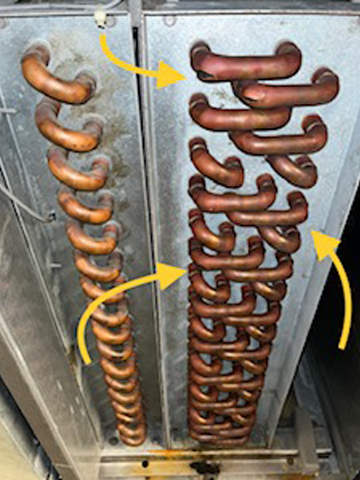

Site Bite: Ruptured U-bends in a Frozen Water Coil

Bundle up, as we go on site with Jack Kessler to assess the all-too-common frozen water coil.

During the winter months, we get a lot of calls for frozen water coils. Like this recent job at a New York City condo complex, where the water froze in a Dunham-Bush® unit rupturing the u-bends.

This particular unit had a 2-row hot water coil and a 4-row chilled water coil with 5/8" copper tubing. Due to its location, the unit used 100% outside air, so when the dampers were open, it was the first unit to be directly exposed to the frigid temps. In a properly functioning unit, the freeze stat (a temperature-sensing device for HVAC units) would prompt the dampers to close when the temps dropped below 32°F. In this case, the freeze stat was broken, and the dampers remained opened. This quickly froze the water inside the copper coils. As water freezes to ice it expands approximately 9% by volume, thus causing the coils to rupture.

To Repair or Replace? That is the Question.

In this instance, a whole new coil was ordered. Often, though, ruptured coils can be repaired via brazing, a metal-joining process where two or more metal items are joined together by melting and flowing a filler metal into the joint. Whether a coil gets repaired or replaced depends on a few factors, including:

• Accessibility of the coil/unit — Damaged u-bends are easier to braze when they’re on the back of coil, rather than the face of the coil.

• Importance of the unit — If the coil is vital and needed every day, brazing is the most immediate, cost-efficient fix. If you have the luxury of time, you can order a coil.

• Age of the coil — depending on how many years the coil has been in service, replacing the coil may be the best option long term.

Do you have a water coil or another type of coil that needs replacing? Email us for a quote. We manufacture custom and OEM replacement coils for every unit, no matter what make, model or year…frozen or not.