Converting MCHX Condenser Coils in a Munters HCUc6030

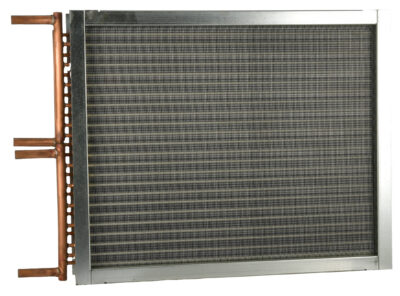

This beneficial upgrade converts the MCHX in three condenser coils to a single copper tube, aluminum fin condenser coil.

Dedicated Outdoor Air Systems (DOAS) have become increasingly common in commercial facilities, as indoor air quality has been a major focal point since COVID. DOAS are specialized HVAC units that condition 100% outside air, independently handling ventilation and humidity control, typically for the entire building.

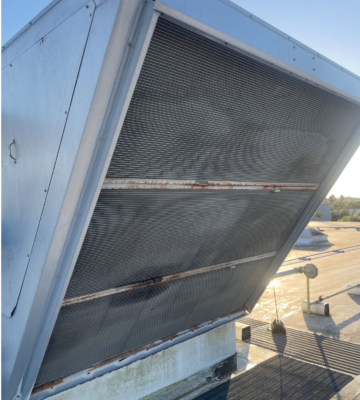

On a recent DOAS project, we encountered a Munters HCUc6030 unit consisting of a DX evaporator coil, a reactivation hot gas reheat coil, plus three all-aluminum microchannel condenser coils. Although this unit is robust and the best at independently controlling temperature and humidity, the three MCHX condenser coils have been a weak point for reliable unit operation. Enter the microchannel upgrade.

On-site, we were able to assess the unit and take exact measurements to replace the three low-grade MCHX condenser coils with a single copper tube, aluminum fin condenser coil with three circuits.

Converting the MCHX condenser coils required minimal re-piping and provided a significant upgrade to the entire system — restoring maximum performance and long-term system functionality.

Benefits of an MCHX Conversion

Upgrading a microchannel to a copper tube, aluminum fin can be done on any type of commercial coil to improve the durability, reliability, and cost-efficiency of the system...

1. Easier Field Repair

Copper tube coils can be brazed and repaired in the field. If a leak develops, technicians can typically isolate and repair the affected area instead of replacing the entire coil, reducing downtime and replacement costs.

2. Improved Serviceability

Copper tube systems allow technicians to pump down and isolate refrigerant into the condenser during service. This can eliminate the need to recover the entire refrigerant charge, saving time and labor.

3. Reliability in Harsh Environments

The highly durable copper tubing can withstand extreme elements and vibration better than thin, aluminum microchannel tubes.

4. Better Tolerance to Contaminants

Copper tube coils are generally more forgiving in systems that may have moisture, debris, or slight contamination. Microchannel coils have very small internal passages that can be more susceptible to blockage.

5. Longer Track Record

Copper tube/aluminum fin coils have decades of proven performance across HVAC applications. Many service technicians are more familiar and comfortable working with them.

6. Compatibility with Existing Systems

Copper tube coils may integrate more easily into older systems or retrofit applications where system design, metering devices, or refrigerant control strategies were originally designed around round-tube coils.

Go With the Pros

Over the years, Nationwide Coils has literally converted thousands of microchannels. Should you be interested in this beneficial upgrade, work with the experts. Call 1.888.CoilPro or email us anytime. All we need is the unit's make and model number to get started.