Converting the Microchannel Coil in the Lennox® LCH156H4: Improve performance and reliability

Combat the leaking issues that are inherent in Lennox’s LCH156H4 rooftop unit and other OEM MCHX coils with a cost-efficient microchannel conversion.

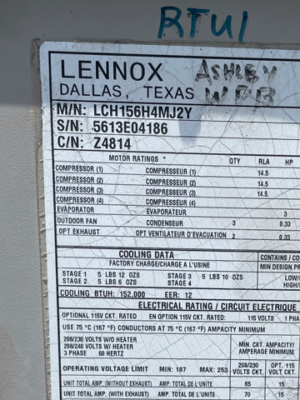

When it comes to replacing commercial condenser coils, the Lennox LCH156H4 is a usual suspect.

Going hand in hand with building a replacement coil for this popular unit is converting its all-aluminum microchannel to a copper tube, aluminum fin coil.

Microchannel coils have become a mainstay in the air conditioning industry for over a decade, not just in Lennox units but with most OEM equipment. As a cheaper material, aluminum coils help keep costs down while reducing the refrigerant footprint. Yet, along with the savings come some significant disadvantages.

The Downside of Microchannel Coils

Microchannel coils tend to get dirty like the filter in your dryer. If they’re not maintained regularly the head pressure of the system can cause operational issues. What’s more, precise refrigerant charge is needed for the equipment to run properly do to the low refrigerant volume of MCHX coils. Additionally, repairing an all-aluminum coil proves challenging, requiring two-part epoxy or a torch. And during repair, aluminum becomes vulnerable to weather conditions. It should be noted that connection leaks are also common where the copper meets the aluminum coil.

#ChangeTheChannel: Upgrading to a Copper Tube, Aluminum Fin Coil

Enter the high-grade copper tube, aluminum fin coil — a microchannel conversion that will not only improve the performance of your Lennox unit but increase its reliability and overall lifespan.

Benefits include:

· Increased durability

· Easier to repair and maintain than microchannel coils

· Ability to pump down the system. Microchannel coils use flat plates with very small holes going through them, reducing refrigerant capacities upwards of 30%. Alternately, when making a system repair with copper tube coils, the compressors can pump the refrigerant into the condenser coils. This avoids having to recover the refrigerant from the entire system prior to making repairs, saving time and money.

· Increased cost efficiency over the life of the coil by reducing repairs and lost refrigerant do to leaks

Completing the Circuit

When replacing the microchannel condenser coil with a copper tube condenser coil, you must complete the circuit. So, if the unit has eight microchannel coils with four per circuit and only one coil is bad, you must replace all four coils to complete the circuit. This is because the amount of refrigerant used per circuit is greater when using the copper tube condenser coils. Plus, the MCHX coil and the copper tube coil have different refrigerant pressure drops. If it were paired with the same circuit, it would cause the unit to have operational issues.

#MastersOfMicrochannelConversion

Although the Lennox LCH156H4 rooftop unit is one of the more popular units that require microchannel conversion, this upgrade is available for any major make and model commercial HVAC unit.

Over the years, we’ve literally converted thousands of microchannels, making Nationwide Coils the #MastersOfMicrochannelConversion. Should you be interested in this beneficial upgrade, work with the experts. Call 1.888.CoilPro or email us anytime. All we need is the unit's make and model number to get started.