Preparing Commercial HVAC Coils and RTUs for Winter

As a triple polar vortex sends temps plunging in central and eastern U.S., learn how to prevent freezing coils and costly downtime of RTUs. Take action now to prepare and protect your commercial HVAC coils and rooftop units.

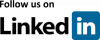

Winter weather can be hard on your steam coils and hot water coils and keeping your heating systems in prime condition takes maintenance. Freezing air, moisture, corrosion and reduced airflow can all lead to frozen coils, high energy bills and unplanned downtime. The key to avoiding those issues is preparing early to protect your commercial HVAC coils (steam distribution coils, standard steam coils, hot water coils, DX evaporator Coils and condenser coils) and keep your RTUs and air handling equipment running efficiently through the coldest months.

1. Inspect and Clean Coils Before Temperatures Fall

Dust and debris left over from summer can block airflow and reduce heat transfer. Dirty DX evaporator and condenser coils for heat pump units force compressors, fans and controls to work harder than needed — and increase the risk of operational issues, especially in RTUs.

Maintenance checklist:

- Clean DX evaporator Coils and condenser coils with manufacturer-approved cleaner

- Remove leaves, dirt and debris from around RTUs

- Straighten bent fins to restore airflow

- Flush drain pans and condensate lines to prevent ice buildup

- Check steam/hot water system

Pro Tip: Schedule a cleaning for your commercial HVAC coils before outdoor temps dip below 50°F (10°C).

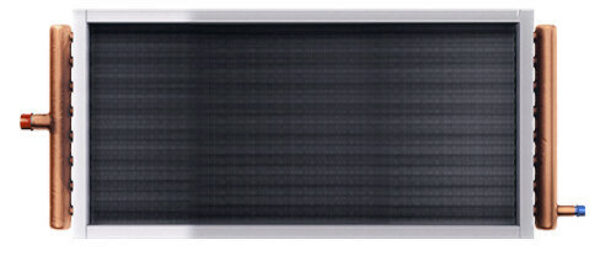

2. Verify Drainage and Freeze Protection on Hydronic Systems

Water or glycol coils must be protected before freezing weather hits. Even a few ounces of water left in the tubes can expand and rupture Hot water coils.

Best practices:

- Confirm that all drain valves and pans are clear

- Test glycol concentration — 30–50% is typical depending on climate

- Inspect low-temperature sensors and automatic drain valves

- Check steam vents and hot water vents to prevent air-bound coil issues

- Check steam drain for proper operation — steam distribution coils and standard steam coils will not operate correctly without a fully functional steam trap

- Label coils by freeze protection type (glycol, electric trace, etc.) so technicians know what to check mid-season

3. Inspect Coil Coatings and Corrosion Protection

Winter air can be wet, salty and corrosive. Over time, this destroys fin surfaces and weakens tube joints in commercial HVAC coils.

Action steps:

- Check existing coil coatings for peeling or damage

- Contact us for the correct process to repair your specific coating

Well-coated commercial HVAC coils can last up to 2× longer in exposed winter environments.

4. Test Defrost and Freeze Protection Controls

Before freezing weather arrives, make sure all protection systems work correctly.

Verify that:

- Heat pumps defrost timers and reversing valves cycle correctly

- Crankcase heaters function to prevent compressor oil thickening

- Low-ambient fan controls modulate condenser fan speed

- Freeze sensors and thermostats respond accurately

Defrost control testing now can prevent frozen commercial HVAC coils — and expensive compressor damage — later.

5. Maintain Airflow Around RTUs

No airflow, no heat exchange. Snow drifts or blocked louvers can cause rooftop unit coils to freeze or compressors to overheat.

Before and during winter:

- Inspect and clear all louvers and dampers

- Add snow guards or screens for RTUs in snowy climates

- Check that fans and motors operate freely

- After storms, visually inspect for ice buildup or blockages

6. Inspect Filters, Belts and Motors

Poor airflow from worn belts or clogged filters can mimic a commercial HVAC coil failure.

To-do list:

- Replace air filters (MERV-8 or higher)

- Inspect and tension belts

- Lubricate fan bearings and motor assemblies

- Verify airflow according to design CFM

7. Perform a Full System Test

Run your HVAC system under low-ambient conditions to ensure it performs correctly before the real cold sets in. This is especially important for heating coils and RTUs that face sustained winter loads.

Confirm:

- Supply/return air temperatures are within spec

- Defrost cycles operate correctly

- Freeze stats are operational

- No abnormal vibration, noise or pressure swings occur

- BAS sensors and alarms read correctly

8. Schedule RTUs for a Mid-Winter Inspection

Even the best-prepared systems can develop ice or corrosion mid-season. A quick January or February inspection, can help you address:

- Frost or ice on outdoor coils

- Early corrosion or salt deposits

- Fan cycling or defrost faults

- Blocked louvers or snow buildup

RTUs are directly exposed to all outdoor environmental elements year-round. This constant exposure necessitates a durable, weatherproof construction and presents specific maintenance challenges.

Winter doesn’t have to be hard on your HVAC system. Preventive maintenance for your commercial HVAC coils and RTUs costs a fraction of the price of emergency repairs and/or building damage. Plus, it keeps comfort and reliability high. With proper cleaning, inspection, freeze protection and airflow management, your commercial HVAC coils and RTUs can run efficiently all season long.

A small investment in winter preparation today can save thousands in repairs tomorrow.

GET A QUOTE today on a custom or OEM replacement commercial HVAC coil.